- 上传者: Administrator

- 上传时间:2024年02月27日 07时23分10秒

Bill of Material** Before creating a manufacturing order, it is necessary to configure the components of the product in the Odoo Manufacturing module. ......

Bill of Material

Before creating a manufacturing order, it is necessary to configure the components of the product in the Odoo Manufacturing module. Using the Bill of Material feature in the Odoo Manufacturing module, you can create the list of raw materials or components required for the production of the product. This Bill of Material can be used while creating a manufacturing order and the components mentioned in the respective BoM will automatically appear in the Components tab of the manufacturing order. Let’s check how this works in the Manufacturing module.

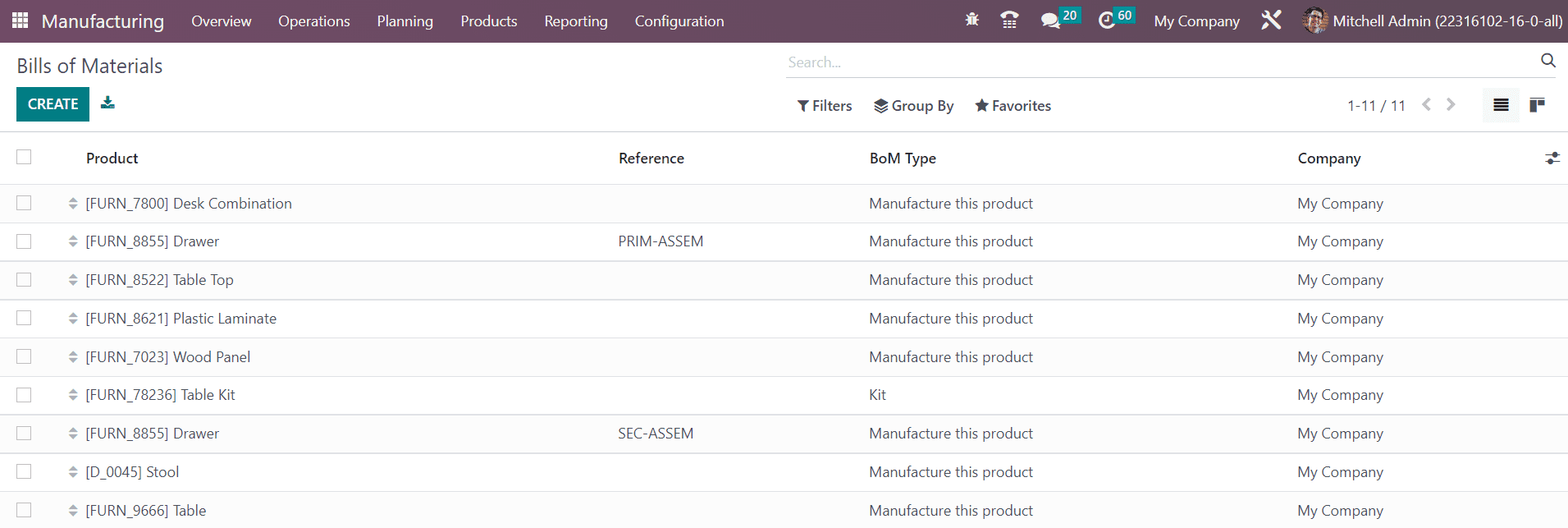

In order to create a Bill of Material for a product, you can select the respective option from the Products menu of the Manufacturing module. The window will show the list of already configured BoM as shown in the image below.

From the list view, you will get the details of the Product, Reference, BoM Type, and Company. You can click on the Create button to create a new BoM.

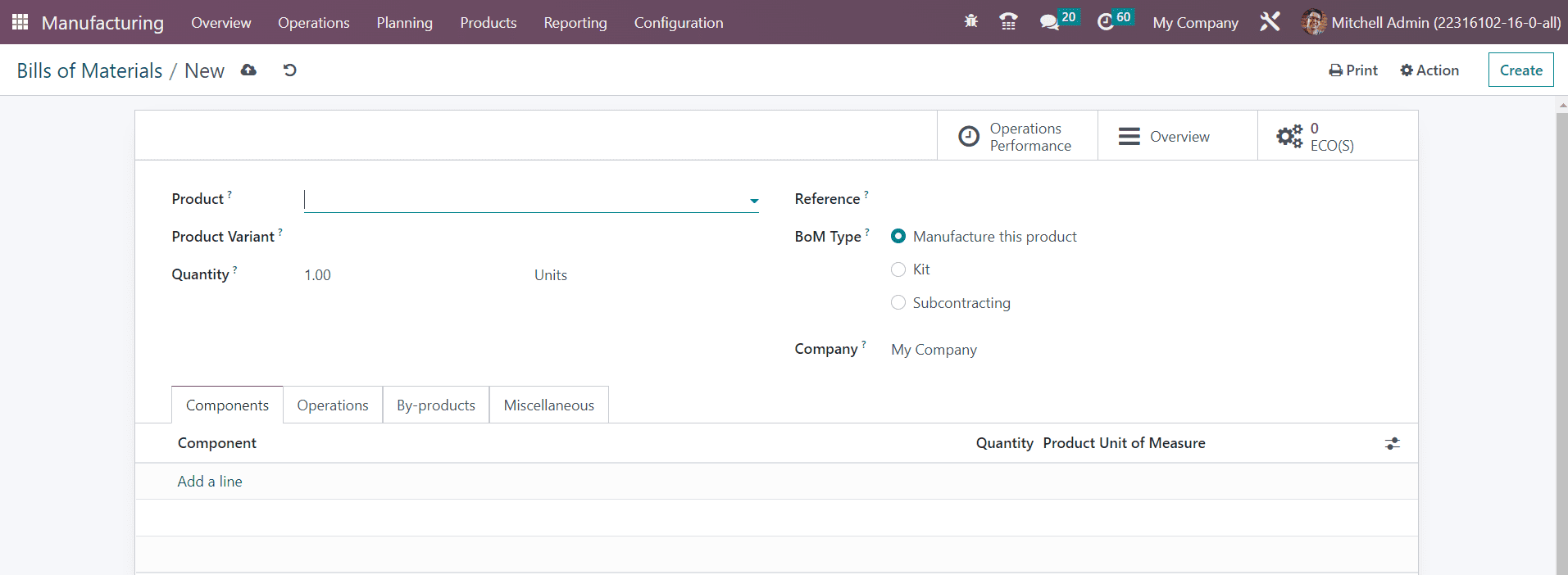

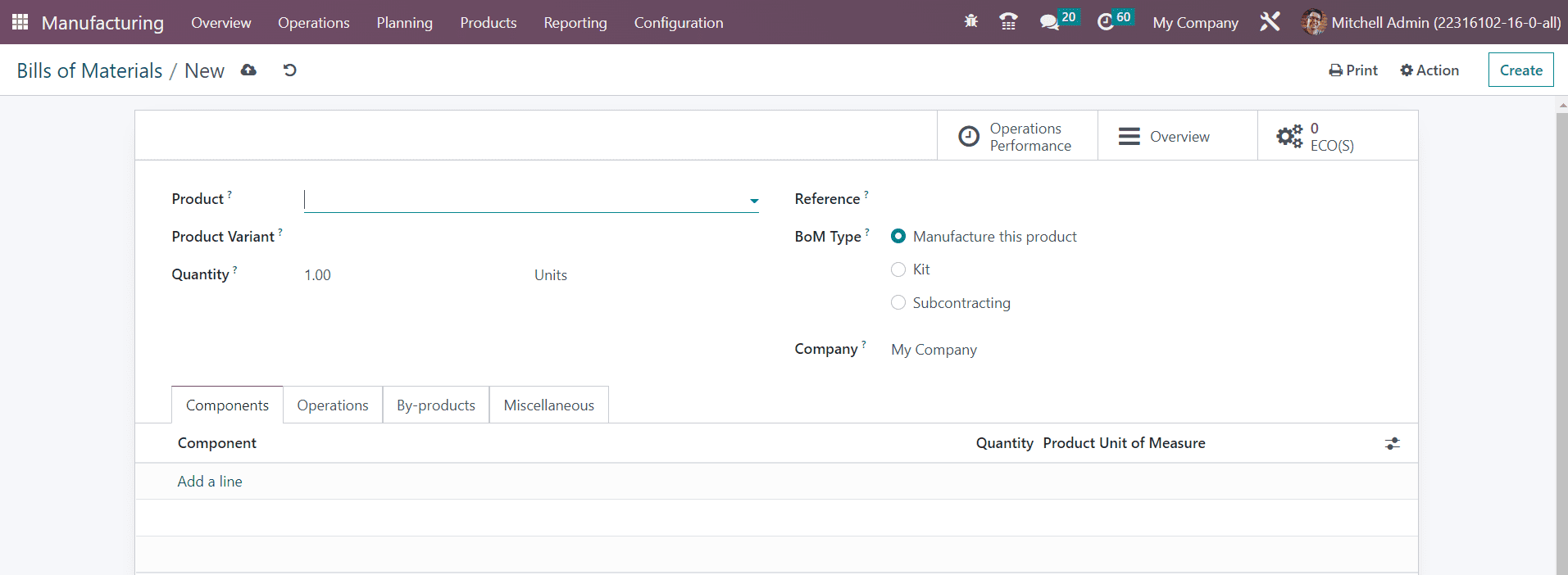

Mention the Product, Product Variant, Reference, and Quantity that you want to manufacture in the corresponding fields.

In Odoo, you can create three types of bills of material. In the BoM Type field, you can select the type as Manufacture this Product, Kit, or Subcontracting. If you are creating this BoM for manufacturing this product, you can select the Manufacture this Product option. Selecting the Kit option will allow you to sell the components of this BoM as a kit. Selecting the Subcontracting type indicates that you are giving this BoM to a subcontractor and the assigned subcontractor will manufacture the product for you using this BoM.

We will take a look at each of these BoM Types separately. First, let’s discuss how to create a BoM for manufacturing a product. Under the Components tab, you can specify the raw materials required to produce the mentioned product one by one using the Add a Line button.

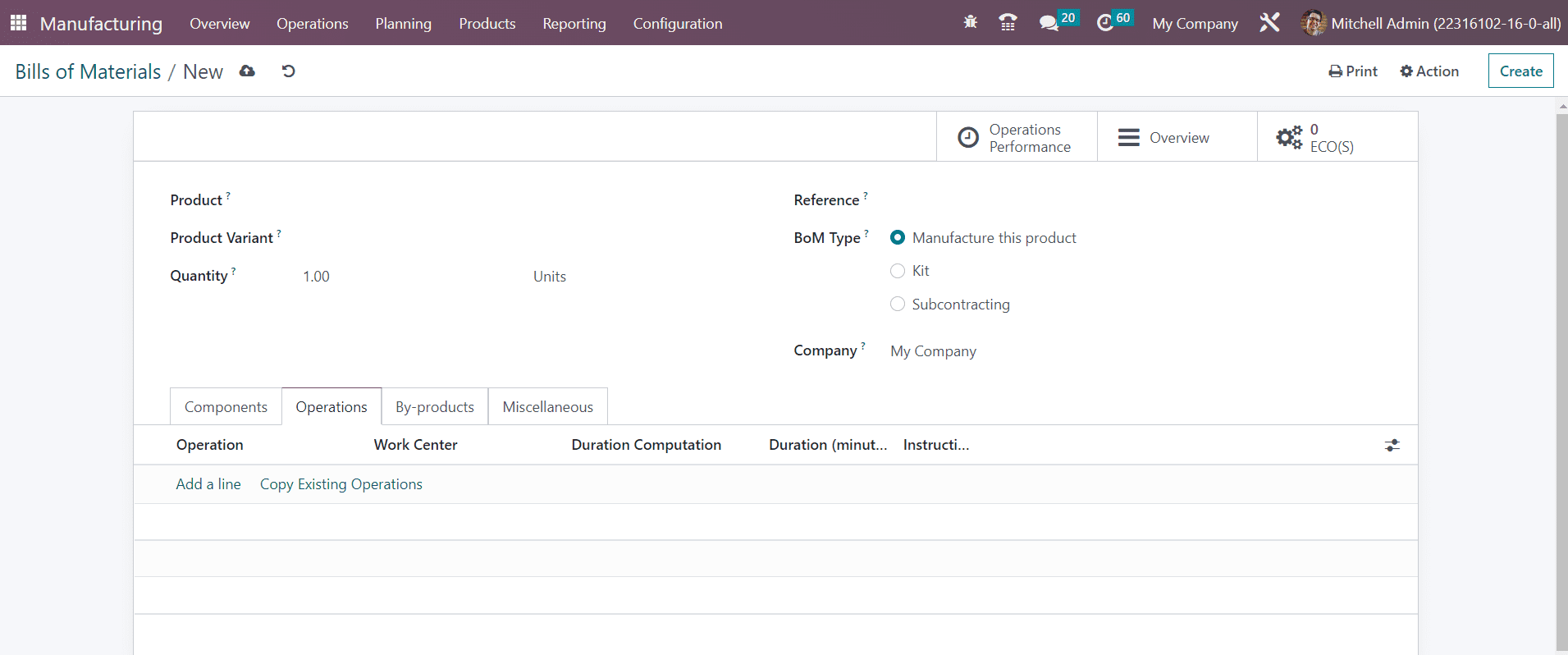

In the Quantity field, don’t forget to mention the quantity of the components required. Now, under the Operations tab, you can add the operations assigned for the work centers to complete the production of the product.

You can copy the existing operations assigned for the product earlier using the corresponding button available in the tab. Or else, click the Add a Line button.

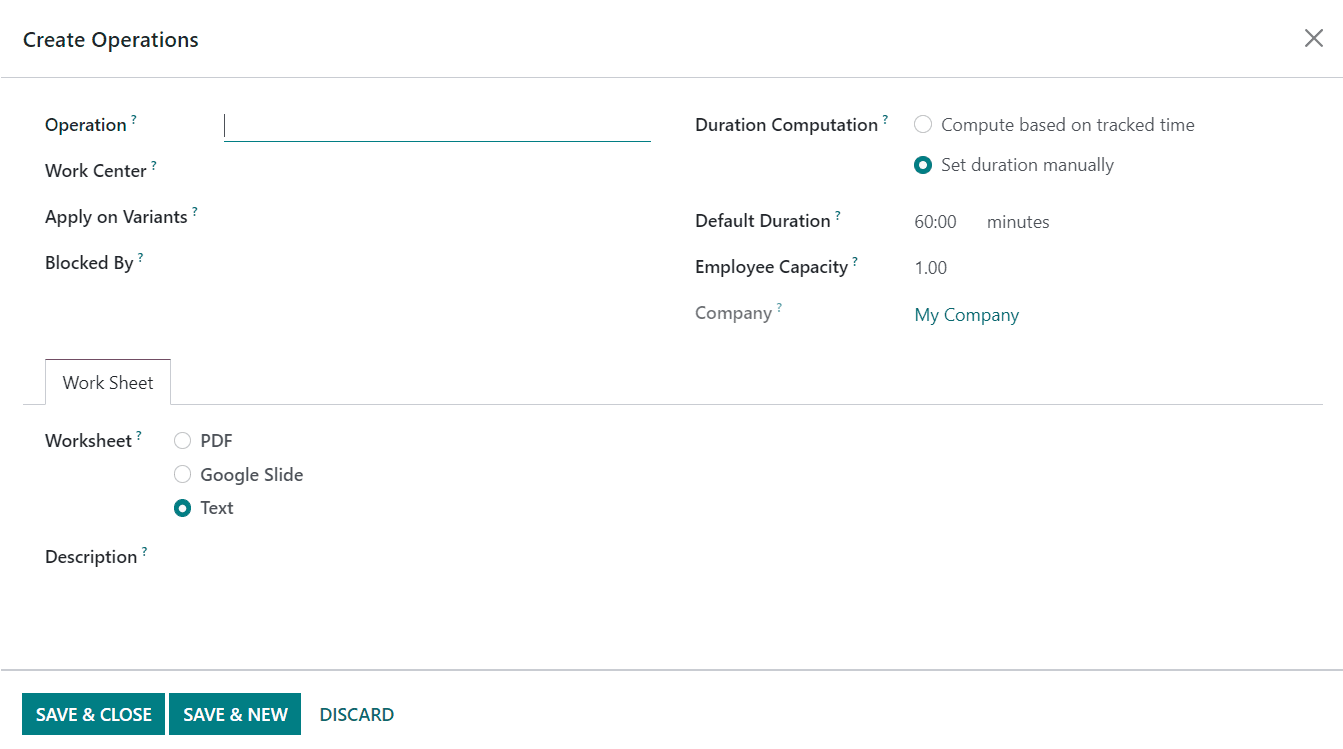

A pop-up window will appear to mention the details of the operation. Mention the Operation and Work Center to perform this operation in the given fields. If the operation is applicable for the product variants also, you can specify them in the Apply on Variants field.

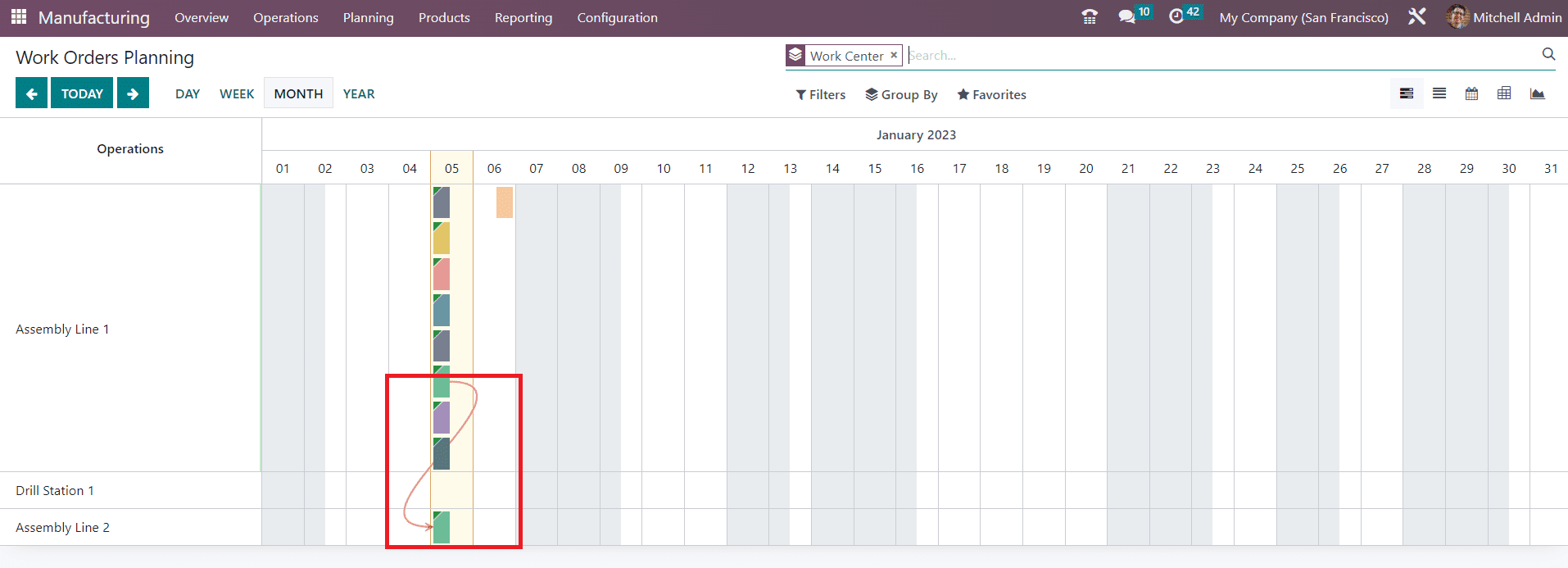

When you activate the Work Order Dependencies from the Settings menu of the module, Odoo will allow you to decide the order to perform the work orders. Under the Miscellaneous tab of the BoM, you will get the Operation Dependencies button to activate, which helps you to decide the order of the operations. Once you activate this feature, you will get the Blocked By field in the Operation window, where you can block other operations to process this operation before the others. From Work Orders Planning, you can see an arrow on work orders to show the order to perform in the Gantt view.

Set the Duration Computation as per your requirement. The duration of the operation can be computed based on tracked time, or you can set the duration manually. The default duration will be available here. The number of employees required to complete this operation can be specified in the Employee Capacity field. You can add the Work Sheet of the operation as PDF, Google Slide, or Text. Along with this, add a Description related to the procedures of the operation in the given space.

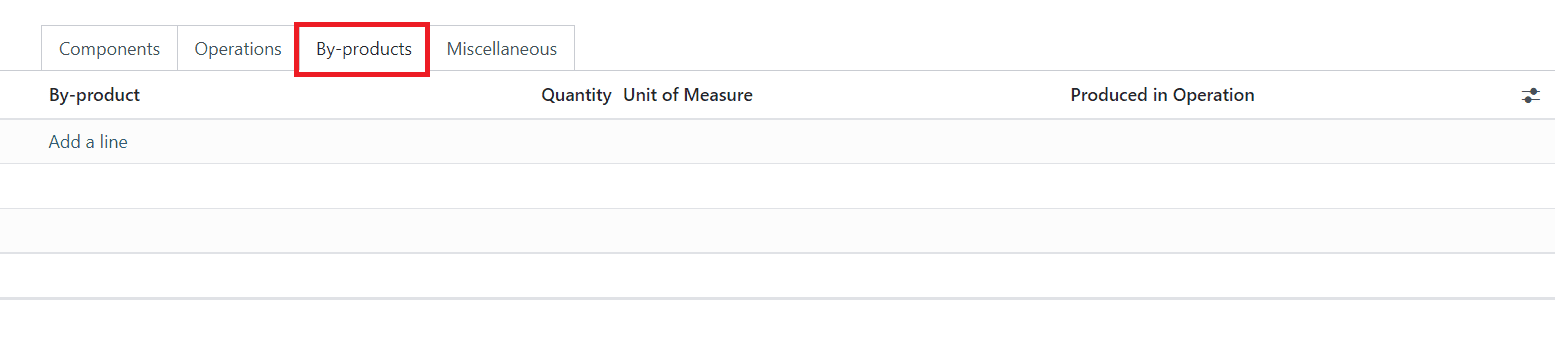

The By-products that come along with the main product can be added under the By-products tab.

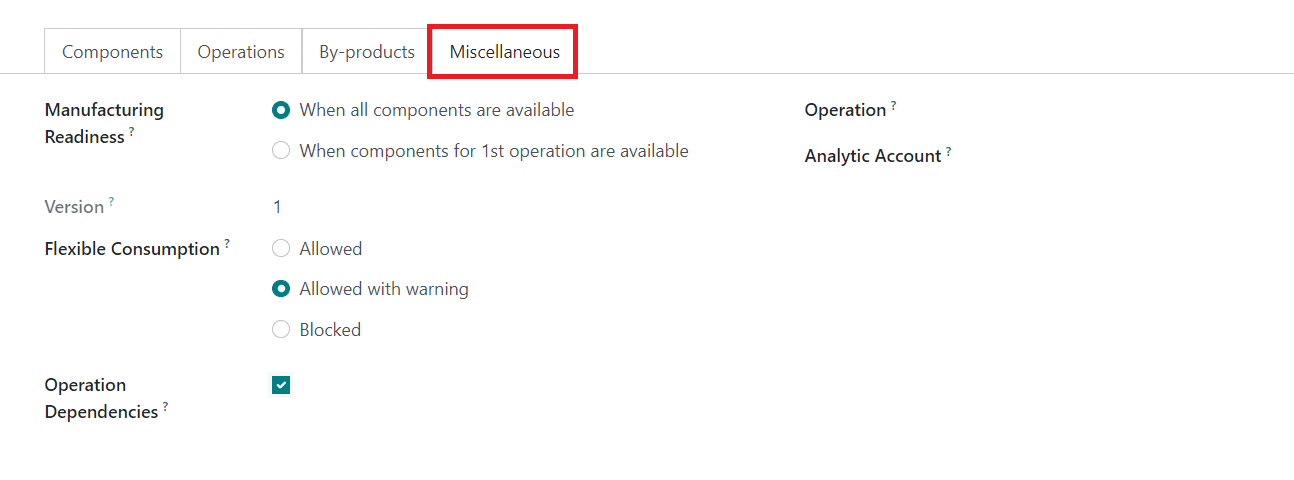

You can define when to start the manufacturing of the product in the Manufacturing Readiness field available in the Miscellaneous tab. If the manufacturing starts only after ensuring the availability of all components, you can set it as When all components are available. If the components are enough to process the first operation, you can start the manufacturing by selecting the When components for 1st operation are available option. The Flexible Consumption will define if you are allowed to consume more or less quantity of components than defined in the BoM. it can be set as Allowed, Allowed with Warning, or Blocked. Activating the Operation Dependencies will allow you to define the order to perform the operations of the BoM. Set an Operation for the BoM, and when procurement has a ‘manufacture’ route with an operation type set, it will try to create a manufacturing order for that product using a BoM of the same operation type. Finally, you can set up an Analytic Account to record the cost and revenue of the BoM.

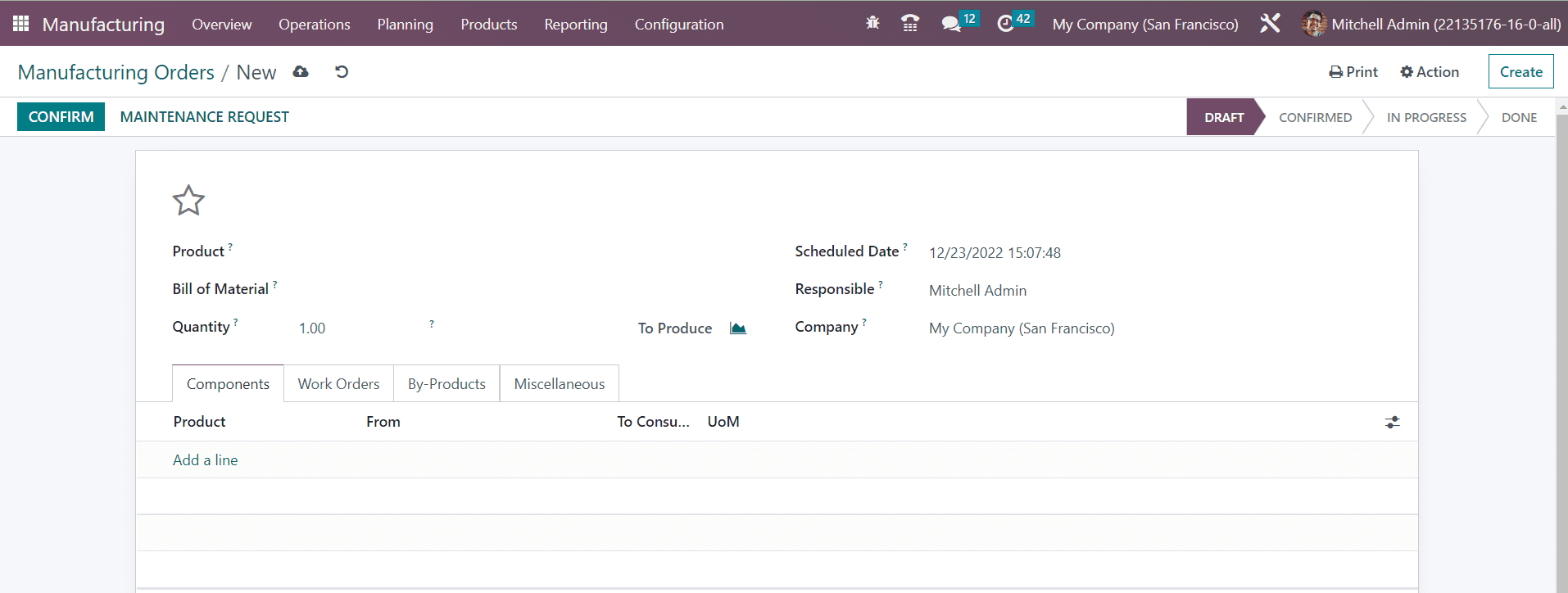

Once you complete the configuration of the BoM, you can use them while creating a manufacturing order for the respective product.

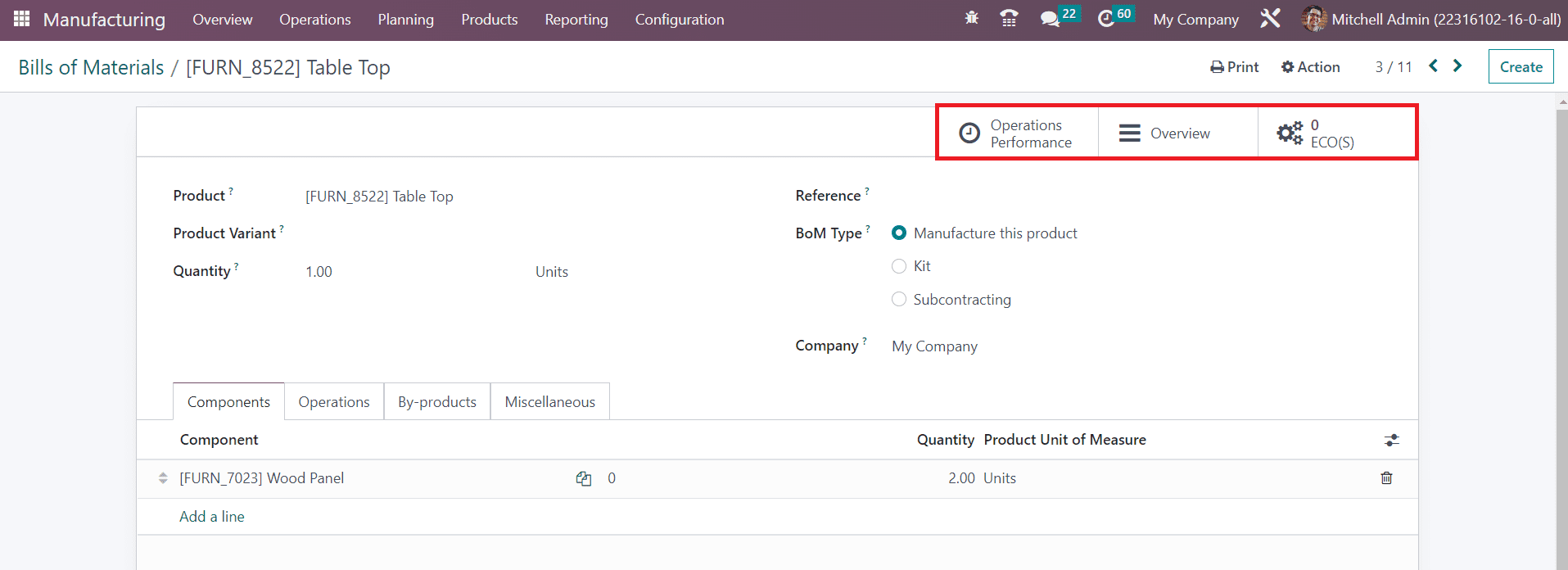

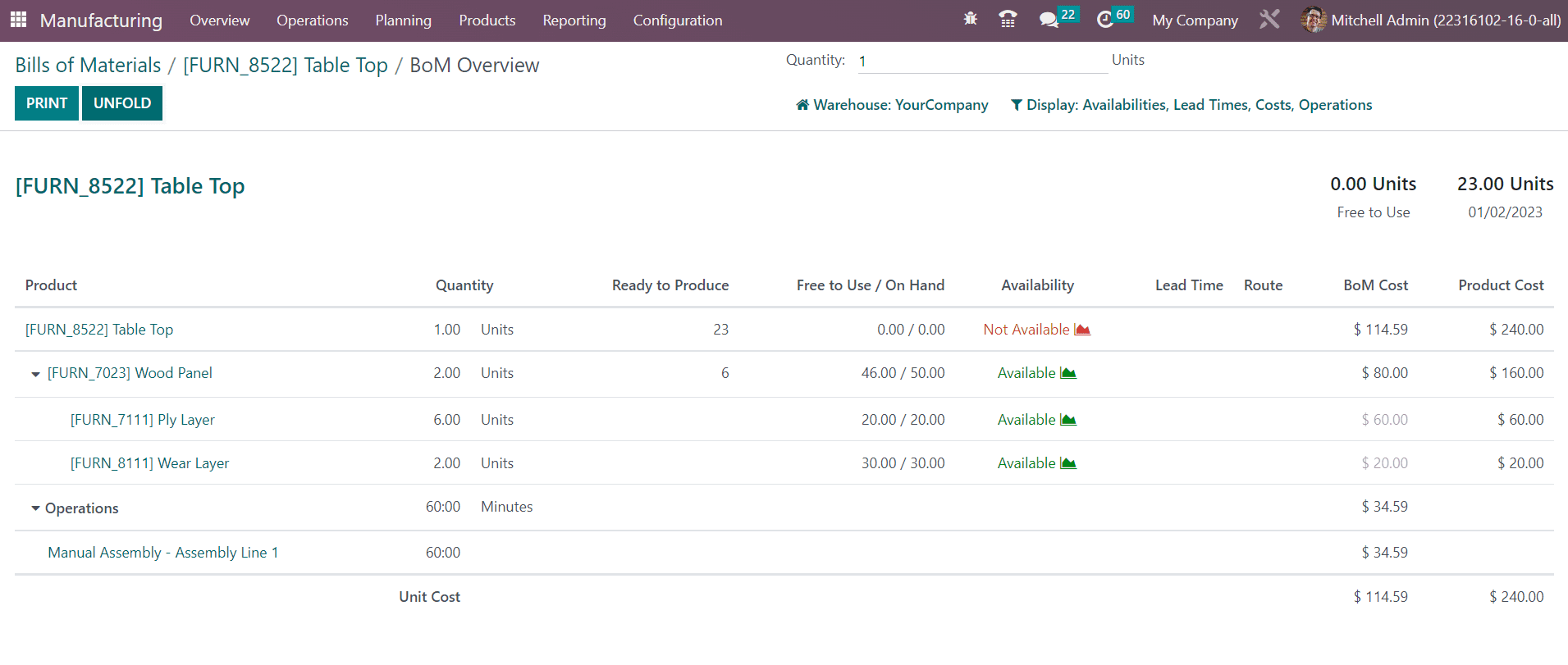

The Operations Performance smart will provide statistics about the work order duration related to this routing. The Overview smart button can be used to get an overview of the BoM as shown below.

It includes the details of the Product, Operations, Quantity, Ready to Produce, Free to Use/On Hand, Availability, Lead Time, Route, BoM Cost, and Product Cost.

The ECO(S) smart button will show the data related to engineering change orders. You can manage your products and bills of materials changes with the assistance of ECOs. This platform will gather related documentation and receive the necessary approvals before applying your changes.

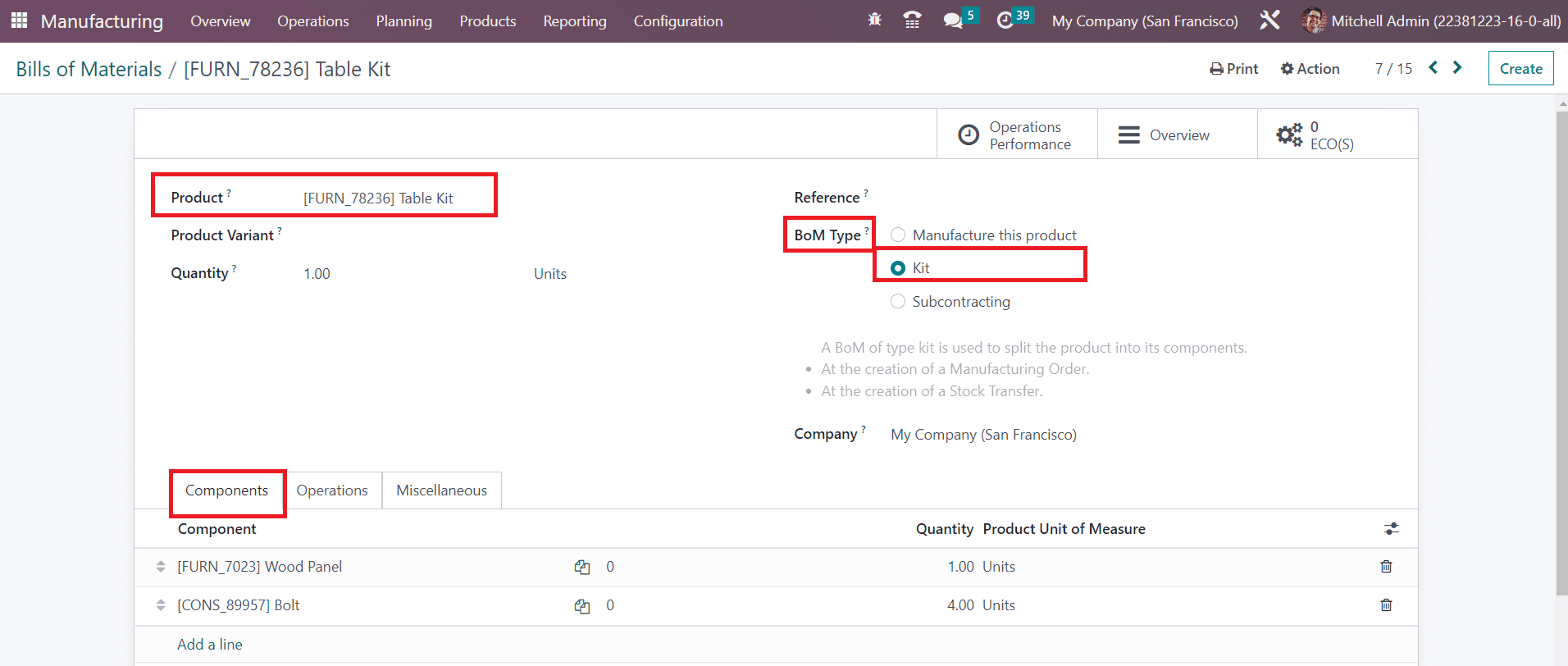

Kit

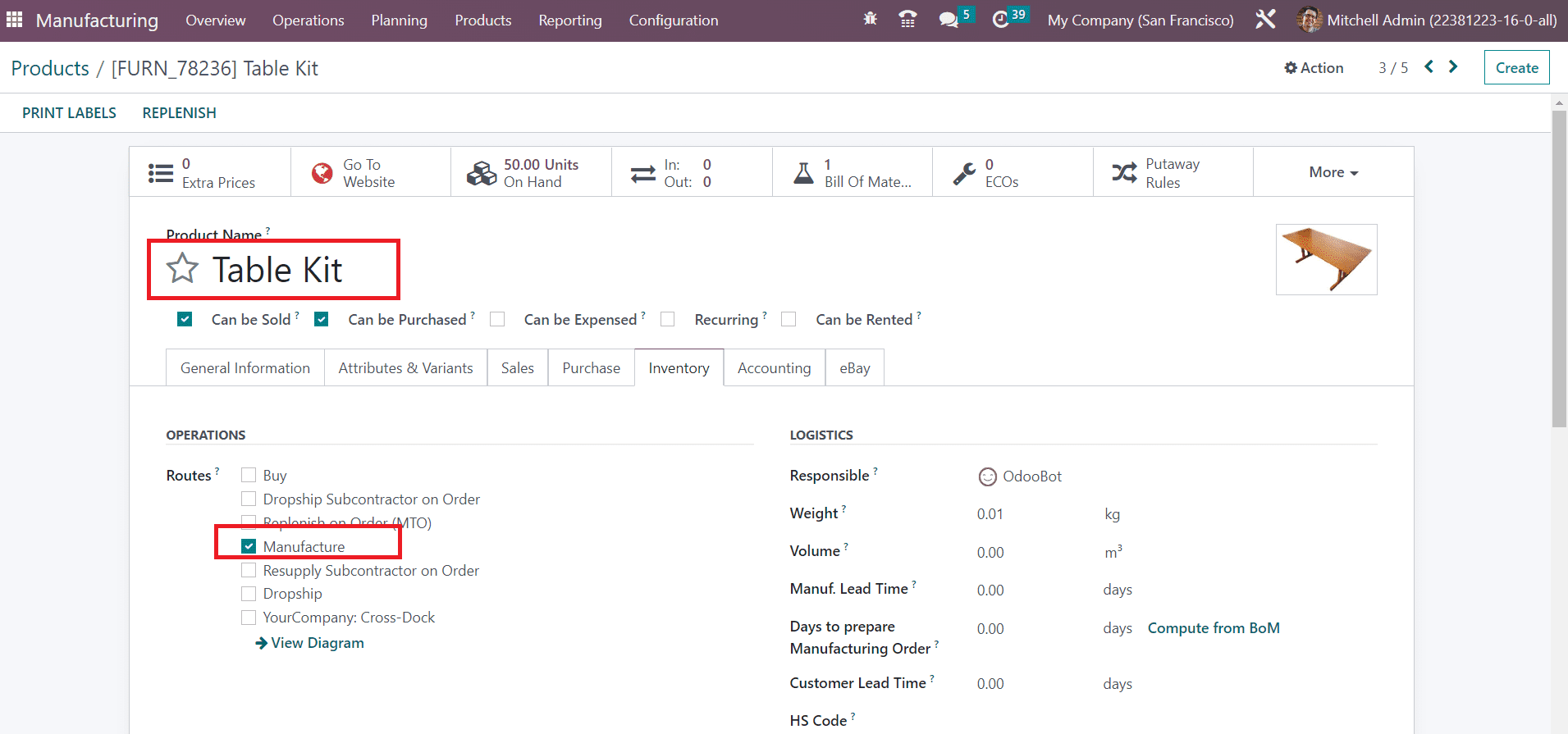

For a product that contains multiple components, you can assemble them as a kit and sell them together. While creating a bill of materials, you will be asked to select the BoM type. Here, you can find the Kit option, which allows you to put the components together in a kit and sell them as a single product. Any inventory adjustment on the kit will also reflect on the individual components. In the Products menu, you can configure a product in the name of the kit and set the Route of Operation as Manufacture as shown in the image below.

Now, you can go to the Bill of Materials configuration platform, where you can create a Bill of Materials for the main product. Select the BoM Type as Kit and specify the Components of the product one by one under the Components tab.

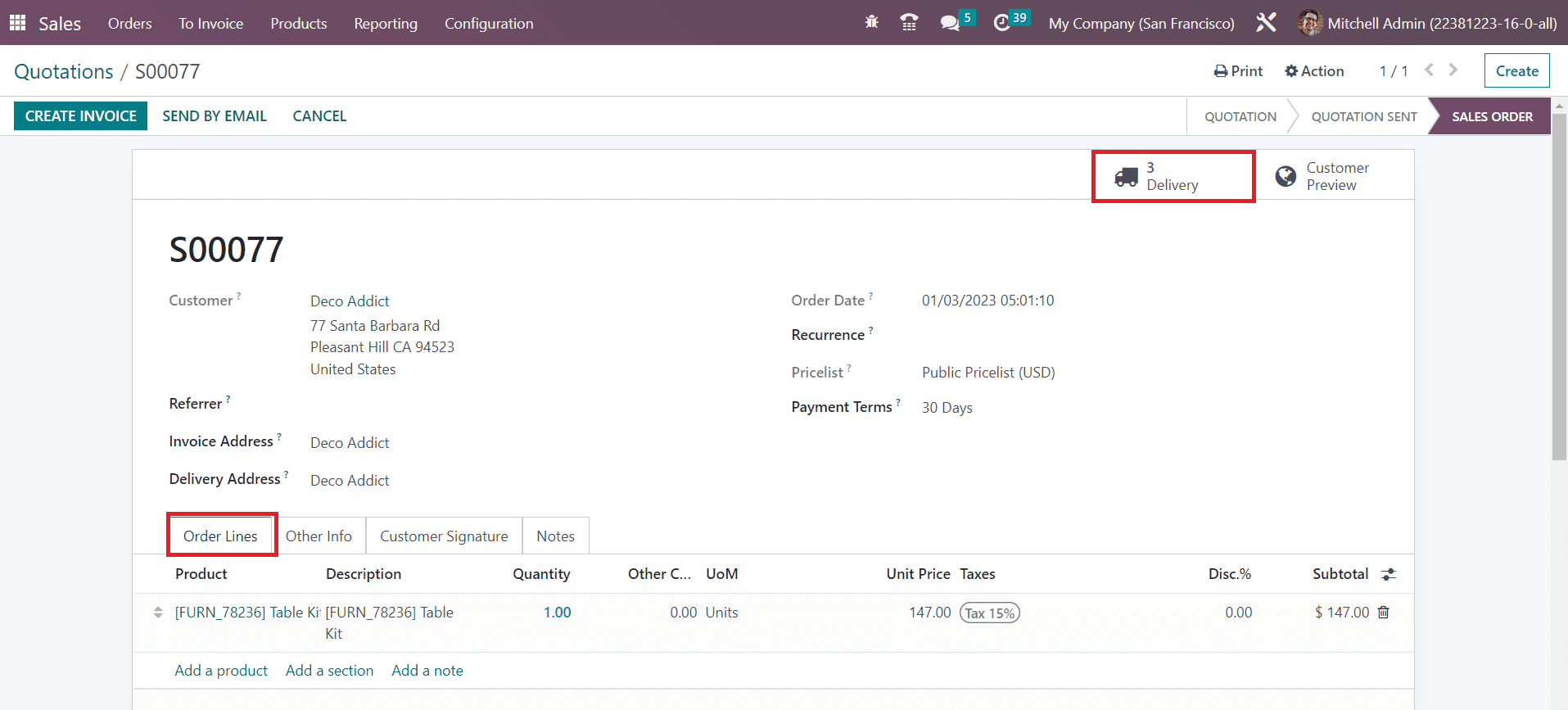

After configuring the Kit, you can sell this product by creating a sales order. In the Order Line of the sales order, you can select the main product.

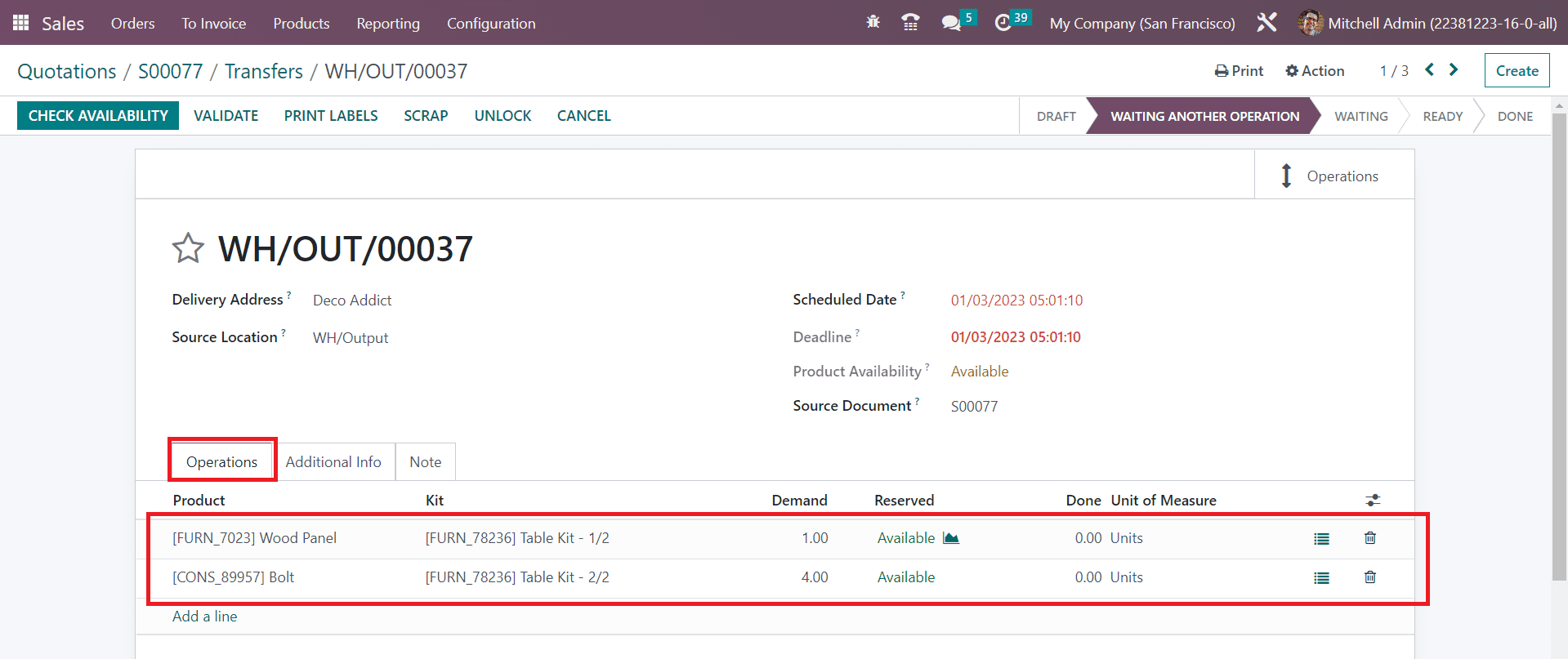

Once you confirm the sales order, check the Delivery Order where you can see the list of individual components of the kit under the Operations tab.

The components which are not available during the confirmation of the sales order can be replenished from the Inventory module.

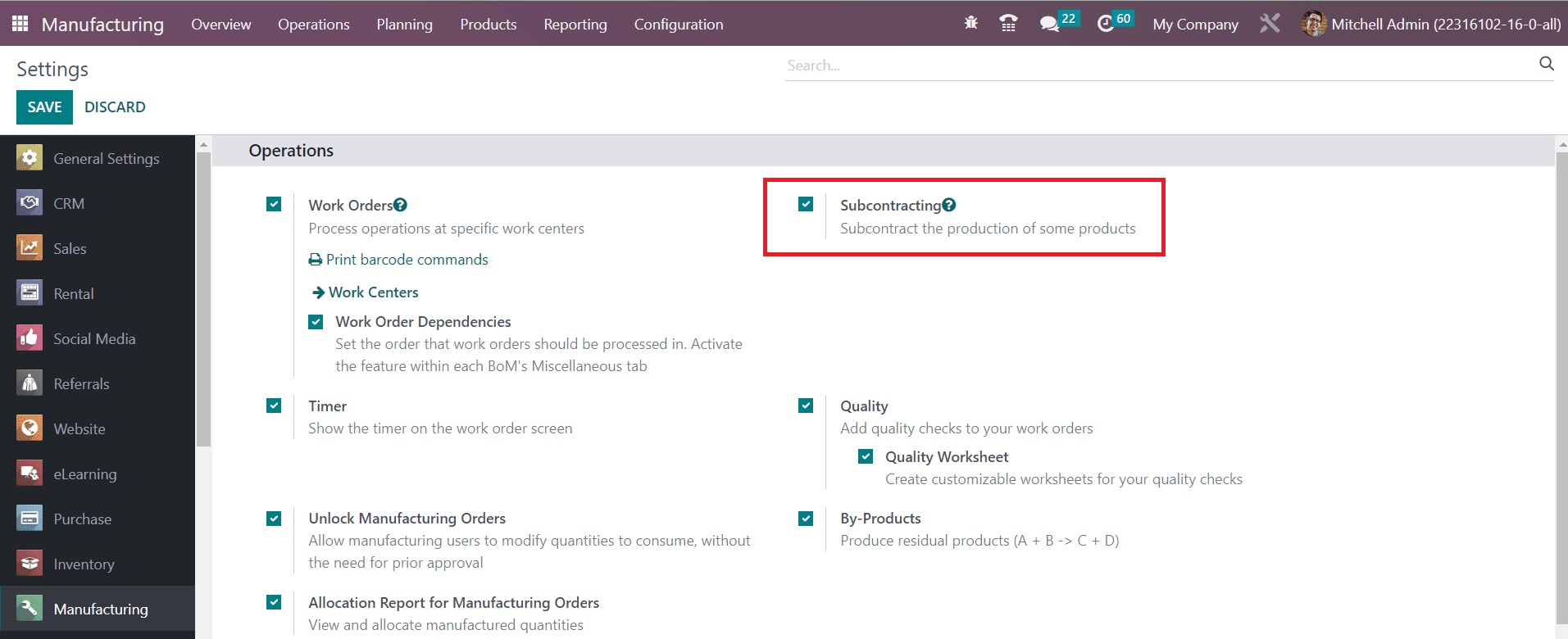

Subcontracting

It is not necessary to manufacture all the components of the products within the company. Through subcontracting, you can assign a subcontractor to manufacture the components and focus more on assembling the purchased components. The inventory of the raw materials will be managed at the subcontractor’s place. In order to get this feature in your Manufacturing module, go to the Settings menu and activate the Subcontracting feature.

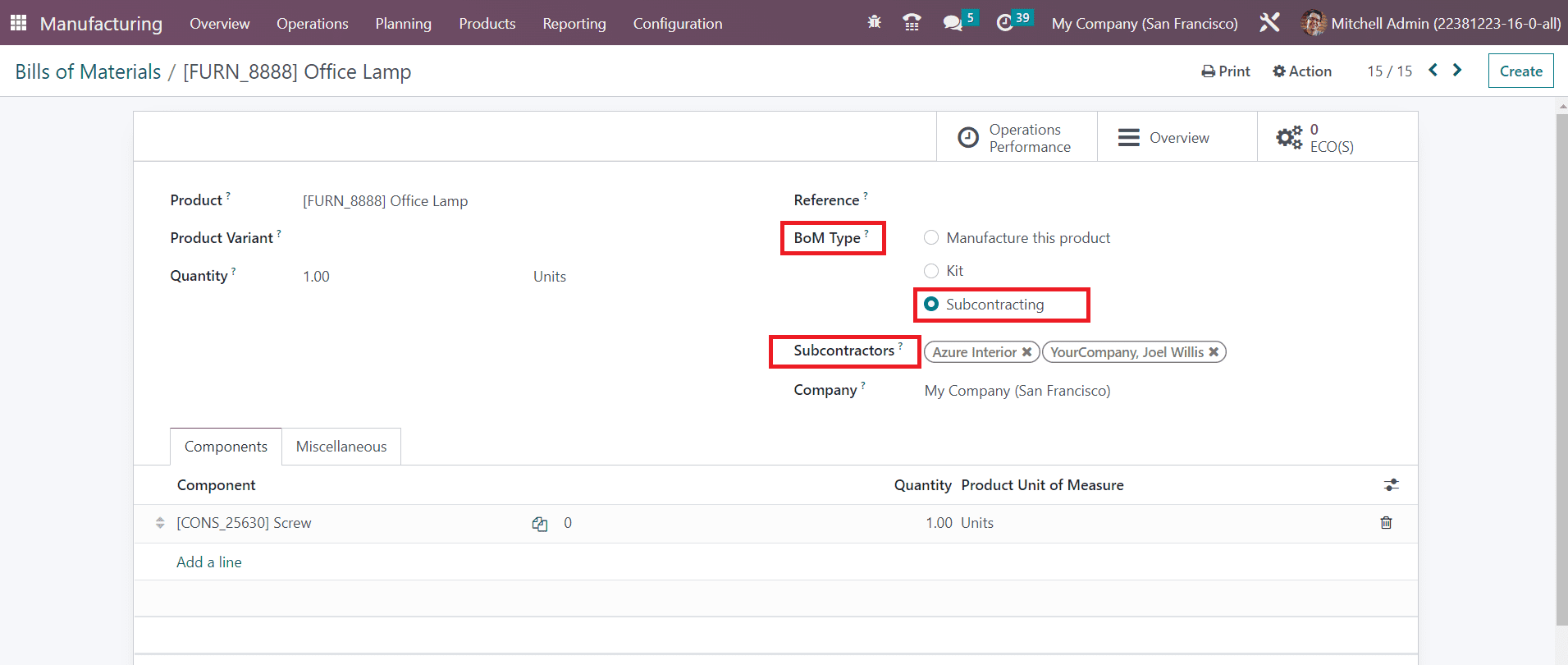

After enabling this feature, you can create a new Bill of Material for the product by selecting the BoM Type as Subcontracting.

You will get an additional field to specify the name of the Subcontractor. Under the Components tab, mention the raw materials and its quantity so that the subcontractor can identify your requirements. After configuring the subcontracting product, you can purchase them from the respective subcontractor by creating a purchase order from the Purchase module.

本文章从网上收集,如有侵权请联系tderp@tderp.com删除- 微信扫一扫,一分也是爱:

-

服务原则及地区范围

宜兴通达网络科技有限公司,地处中国宜兴环科园内,是一家高新技术企业。公司在企业网络维护和企业信息化建设与咨询方面,有10多年经验。

我公司愿与客户一道,力求彻底解决客户问题!

我们不是在给企业提供“头痛医头、脚痛医脚”的暂时解决方案,而是在部署根本性安全与稳定服务!!

我们愿携手客户,建立企业IT规划;杜绝随意安装系统、软件等操作;力求共同维护有序、安全、稳定的网络办公环境!!!

IT服务,服务是根本,客户是上帝;我们提供快速响应、快速上门、快速排查,提供优质高效的服务!!!!

通达科技提供全国范围内的服务,服务形式包括远程协助、电话咨询、电子邮件咨询、传真咨询、问答平台的问题解决等。

宜兴地区提供上门服务:

- 市区服务:宜城街道、城北街道(屺亭街道)、新街街道、新庄街道、环科园、渚桥开发区

- 市郊服务:张渚镇、西渚镇、太华镇、徐舍镇、官林镇、杨巷镇、新建镇、和桥镇、高塍镇、万石镇、周铁镇、芳桥镇、丁蜀镇、湖父镇。